Intshayelelo

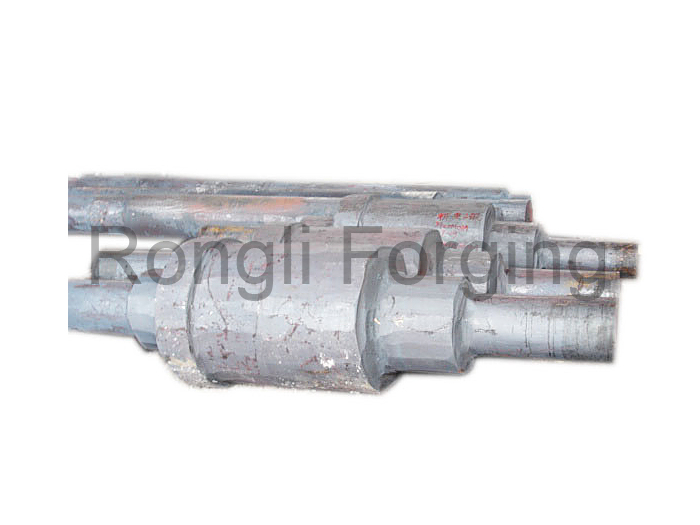

I-Rongli Forging Co., Limited iyakwazi ukubonelela ngeshafti eyenziwe ngoomatshini kunye noomatshini ukuya kuthi ga kwi-20 yeemitha (iinyawo ezingama-66) ubude kunye neetoni ezingama-70 (44,000 lbs.) ubunzima. Iintlobo ngeentlobo zamabanga wemathiriyeli ukuya kwimigangatho eyahlukeneyo ziyasebenza apha kwivenkile yethu yale mihla. Iishafti zethu ezithethwa kakhulu zithunyelwa kuMntla Melika, eYurophu, eOstreliya, eMzantsi Afrika, kumashishini oKwakha iinqanawa, ukuvelisa amandla, umgodi kunye nokulungiswa kwesinyithi, oomatshini abanzima, isinyithi, njl.

Izinto eziphathekayo

| Umgangatho | |||||

| amantla Emelika | Jemani | eBritani | ISO | EN | eTshayina |

| AISI/SAE | I-DIN | BS | GB | ||

| 304 | X5CrNi18-10 | 304S15 | X5CrNi18-10 | X5CrNi18-10 | 0Cr19Ni9 |

| 316 | X5CrNiMo17-12-2 | 316S16 | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 | 0Cr17Ni12Mo2 |

| X5CrNiMo17-13-3 | 316S31 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | |

| 1020 | C22E | C22E | 20 | ||

| 1035 | C35E | C35E | C35E4 | 35 | |

| 1040 | C40E | C40E | C40E4 | 40 | |

| 1045 | C45E | C45E | C45E4 | 45 | |

| 4130 | 30CrMoA | ||||

| 4140 | 42CrMo4 | 708M40 | 42CrMo4 | 42CrMo4 | 42CrMo |

| 4330 | 30CrNiMo | ||||

| 4340 | 36CrNiMo4 | 816M40 | 40CrNiMo | ||

| 50B | E355C | S355JR | Q345 | ||

| 4317 | 17CrNiMo6 | 820A16 | 18CrNiMo7 | 18CrNiMo7-6 | 17Cr2Ni2Mo |

| 17CrNiMo7 | |||||

| 30CrNiMo8 | 823M | 30CrNiMo8 | 30CrNiMo8 | 30Cr2Ni2Mo | |

| 30 | |||||

| 34CrNiMo6 | 817M40 | 34CrNiMo6 | 36CrNiMo6 | 34CrNiMo | |

| Umphezulu wePlunger unokwenziwa lukhuni ngokufakwa kwe-welding ye-2Cr13 ukuya kwi-45-50 HRC. | |||||

Indlela yokubumba: Ukuvula idiyizi evulekileyo / ukufoja simahla

1. Izinto eziphathekayo: Intsimbi yeCarbon, insimbi ye-alloy, insimbi engenasici

2. Umgangatho wezinto eziphathekayo: DIN/ ASTM/AISI/ASME/BS/EN/JIS/ISO

3. Iipropati zoomatshini: Ngokwemfuno yomthengi okanye umgangatho.

4. Ubunzima: Ukuya kuthi ga kwi-70 yeeToni zokugqiba ukubumba. Iitoni ezingama-90 ze-ingot

5. Ubude: Ukuya kuthi ga kwi-20 yeemitha zokubunjwa

6. Ubume bokuhanjiswa: Ubushushu bunyangwa kunye nomatshini orhabaxa

7. Amashishini: Ukwakhiwa kweenqanawa, ukuveliswa kwamandla, umgodi kunye nokucutshungulwa kwesinyithi, oomatshini boshishino olunzima, i-metallurgy, njl.

8. Ukuhlolwa: Uhlalutyo lwekhemikhali nge-spectrometer, uvavanyo lwe-Tensile, uvavanyo lwe-Charpy, uvavanyo lobunzima, uvavanyo lwe-Metallurgy, uvavanyo lwe-Ultrasonic, uvavanyo lwe-Magnetic Particle, uvavanyo lwe-Liquid Penetration, uvavanyo lwe-Hydro, uvavanyo lwe-Radiographic lunokusetyenziswa.

9. UQinisekiso loMgangatho: Ngokwe-ISO9001-2008